Jacketed flush bottom tank valve introduction

Jacketed flush bottom tank valve is mainly used for discharging, discharging, sampling at the bottom of reaction kettle, storage tank and other containers and no-dead zone shut-off operation, in addition to phosphorus and phosphorus light medium, hydrofluorocarbon, hydrochloric acid, sodium hydroxide potassium hydroxide, Jacketed flush bottom tank valve is suitable for all kinds of acid, alkali, salt solution and organic solvent. Jacketed flush bottom tank valve is easy to operate, free to open, flexible and reliable movement;The assembly and maintenance of the disc are simple, the sealing structure is reasonable, and the replacement of the sealing ring is convenient and practical.

Jacketed flush bottom tank valve is mainly used in petroleum, chemical industry, metallurgy, pharmaceutical and other systems to transport high viscosity medium that will solidify at room temperature.The jacket of Jacketed flush bottom tank valve is soldered on the body of the discharge valve, and the side of the Flush bottom jacketed discharge valve is provided with a connecting port of the jacket.Due to the addition of the jacket, the size of the connecting flange of the discharge valve is one to two specifications larger than that of the common ball valve of the same specification, but the structural length is the same as that of the discharge valve of the same specification, the jacket can flow freely through steam or other hot insulation medium, to ensure that the viscous medium can flow smoothly through the hFlush bottom jacketed discharge valve.

Jacketed flush bottom tank valve performance

Nominal diameter: DN15 ~ 300mm;

Nominal pressure: PN1.0 ~ 4.0 Mpa;150LB-300LB

Body material: WCB cast steel, stainless steel, etc

Connection: flange connection, welding;

Driving device: manual, gear drive, electric, pneumatic;

Suitable medium: glue, asphalt and other liquid easy to crystallize and solidify

Design standard: GB/T12233, GB/T12235, ANSIB16.34;

Structure length standard: GB/T1221, HG/T 3704, ASME B16.10;

Pressure test standard: GB/T13927, API598;

Jacketed flush bottom tank valve Performance and advantages

1. Jacketed flush bottom tank valve has a smooth surface.Not easy to bond materials, easy to clean.

2. Resistance to general inorganic acid, weak alkali liquor of organic acid (P≤60℃, PH≤12) and organic agent medium.

3. Heat resistance, it is allowed to be used between -30℃ and 240℃ (sudden temperature resistance is less than 120℃).

4. Insulation: The glass material has good insulation. The glass with a thickness of 1mm will not be broken down and conduct electricity at a high pressure of 2000 volts.

5. Impact resistance: The impact resistance is smaller than 2500 g/cm, so the impact of hard objects should be avoided when using.

Jacketed flush bottom tank valve working principle

Jacketed flush bottom tank valve can be divided into up-show or down-show discharging, up-show handwheel to the right to turn off, to the left to turn on, down-show handwheel to the right to turn on, to the left to turn off, the valve body is V-shape, and provides two working modes of lifting and dropping disc.

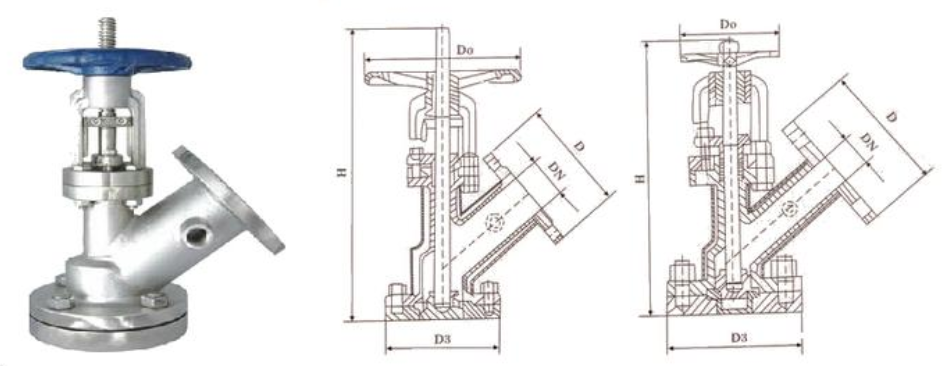

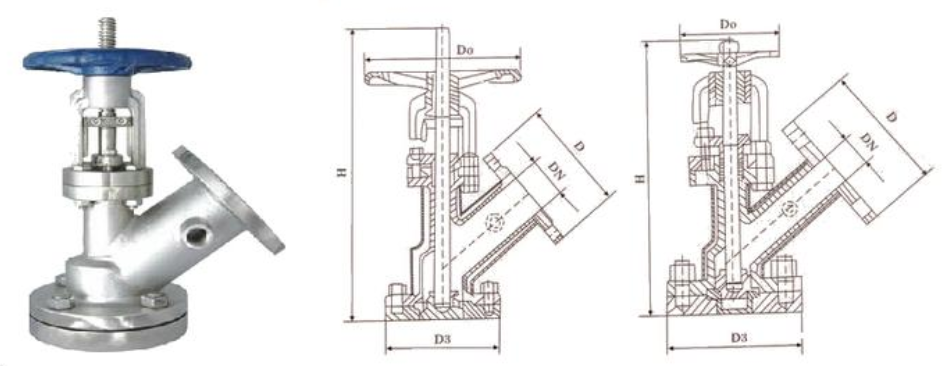

Jacketed flush bottom tank valve structure