Mobile:+86-17717520739

Email:info@shxvalve.com

Address: NO.720, Suide Road, Jiading District,Shanghai, China.

Model:

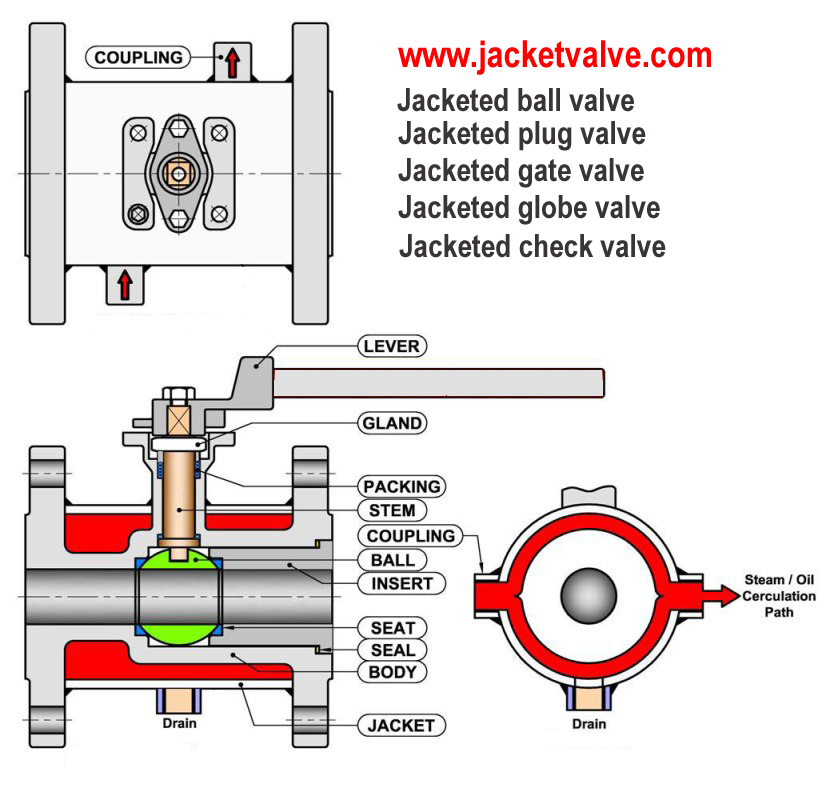

Full Jacketed Ball Valve is largely use to sustain process media temperature during process to keep fluids at a lower viscosity to operate valve smoothly. Full Jacketed Ball Valve is widely used in Food Process,fertilizer Industries,Molten Sulfur / Liquid Sulphur,High Viscous Process Media,Bitumen / Asphalt / Coal tar/ Pitch process application and other anti-crystallization and heating insulation industry system.

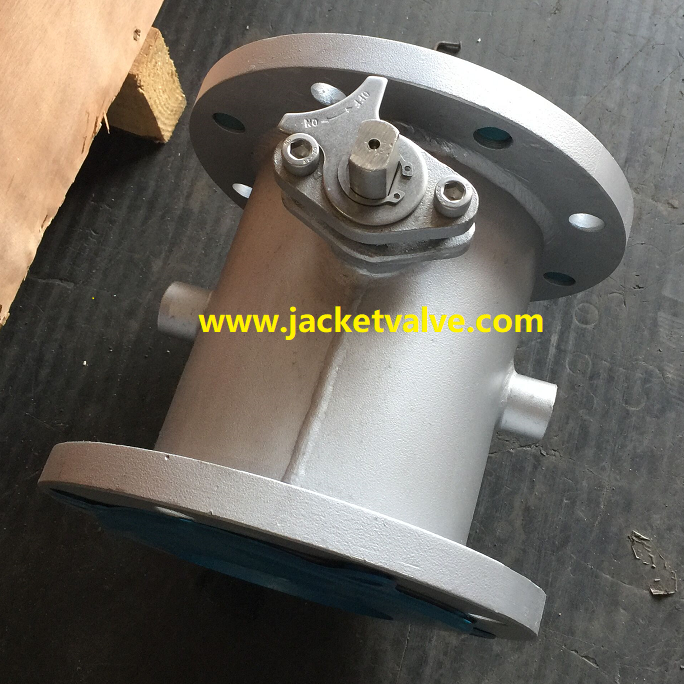

Full Jacketed Ball Valve is Fully Jacketed Ball Valve design. The jacket covers the body from one flange to the other flange. The body of Full Jacketed Ball Valve is modified by adding oversize flanges. As example: 2" x 3" Full Jacketed Ball Valve has the nominal bore of 2" (DN 50) and the flange size is 3"(DN 80). It allows enough space for bolting clearance.

We are Full Jacketed Ball Valve manufacturer in size starts from DN15 x DN 40 (1/2″ X 1-1/2″) to DN150 x DN250 (6″ x10″).

The Jackets assure consistent valve Heating or Cooling of the process media to prevent crystallization or seizing of flow media. The Full Jacketed Ball Valve with very well design to help the high temperature steam or oil flow over the valve ball & body parts to keep the media liquid.

FULL JACKETED BALL VALVE OPERATION: Jacketed Ball Valves are generally supplied with manual hand lever or gear unit operated, depending on valve size.we also offering Ball Valves with either Pneumatic or Electrical actuator operated for automation.

FULL JACKETED BALL VALVE BODY MATERIAL: Cast Carbon Steel (WCB), Cast Stainless Steel (SS304-316-304L-316L,CF8/CF8M/CF3/CF3M), Low Temperature Carbon Steel (LC1/LCB/LCC), Duplex Steel (D2205), Super Duplex Steel (D2207), Hastelloy (HC-C22/HC276), Alloy 20 (CN7M) etc.